008613968780263

008613968780263

Choosing the right Stainless Steel Shielding Frame is crucial for various applications. These frames provide essential protection against electromagnetic interference. However, the selection process can be tricky.

When looking for a Stainless Steel Shielding Frame, consider the environment. Factors like temperature, humidity, and exposure to corrosive elements matter. Each application has unique requirements. You might feel overwhelmed by choices. Take the time to analyze your specific needs carefully.

The right frame will enhance performance. A poorly chosen frame can lead to failures. This can result in increased costs and frustration. Reflect on your past experiences. Have they influenced your current decision-making? Keep these thoughts in mind as you navigate your options. Ultimately, the goal is to find a durable and effective solution.

When selecting a stainless steel shielding frame, consider the material quality. Not all stainless steel is the same. Look for frames made from high-grade stainless steel. This ensures better resistance to corrosion and wear.

It's also vital to assess the size and fit. A misaligned frame can lead to ineffective shielding. Measure your equipment carefully. Ensure that the frame fits snugly. An oversized frame might not provide adequate protection.

Tips: Checking for certifications can help. Look for frames that meet industry standards. This reduces the risk of choosing subpar products. Additionally, think about the frame's design. A well-designed frame can enhance functionality. Lastly, weigh practicality against aesthetics. Sometimes, the best-looking frame may not be the best in performance.

When selecting stainless steel for shielding applications, understanding the types is crucial. Stainless steel grades vary in composition and characteristics, impacting their performance. For instance, 304 stainless steel is common but not always ideal for high-radiation environments. Its composition includes 18% chromium and 8% nickel. This balance provides good corrosion resistance but can fall short in advanced shielding scenarios.

On the other hand, 316 stainless steel offers enhanced durability. This grade features molybdenum, which elevates its resistance to pitting and crevice corrosion. Data from industry reports show that 316 can perform better than 304 in marine and chemical environments. However, it is important to note the higher cost associated with 316. This might lead some projects to reconsider their budget, balancing performance with expenditure.

Another type to consider is duplex stainless steel. This hybrid offers high strength and resistance to yellowing under radiation, but it may be overkill for less demanding situations. Some users feel uncertain about optimal thickness and design. Balancing these attributes requires careful thought. The decision-making process can be complex, asking whether the additional investment is justified for specific applications.

When choosing a stainless steel shielding frame, durability and corrosion resistance are critical factors. Stainless steel comes in various grades, affecting its longevity. For instance, Type 304 stainless steel offers good corrosion resistance but may require more frequent maintenance in harsh environments. In contrast, Type 316, which contains molybdenum, provides superior resistance to saltwater and chlorides. According to industry reports, Type 316 can last up to 50% longer in corrosive settings compared to Type 304.

In addition to material grade, the manufacturing process also influences durability. Welding techniques and surface finishes can impact the frame's resistance to environmental factors. A rough surface may trap moisture, leading to corrosion. On the other hand, polished finishes tend to repel substances that cause rust. Research shows that properly finished stainless steel can endure exposure to acidic environments for years. However, improper handling during installation can negate these benefits.

It's also essential to consider the frame's application. Frames subjected to high mechanical stress must be assessed for fatigue resistance. Some reports indicate that wear and tear can reduce a frame's lifespan by 30% if not properly evaluated for operational demands. Filtering through this information requires attention to detail. It's easy to overlook these considerations, which can lead to costly replacements down the line.

This chart illustrates the assessment of durability and corrosion resistance of different types of stainless steel used in shielding frames. The data indicates the performance of various alloys based on standardized tests.

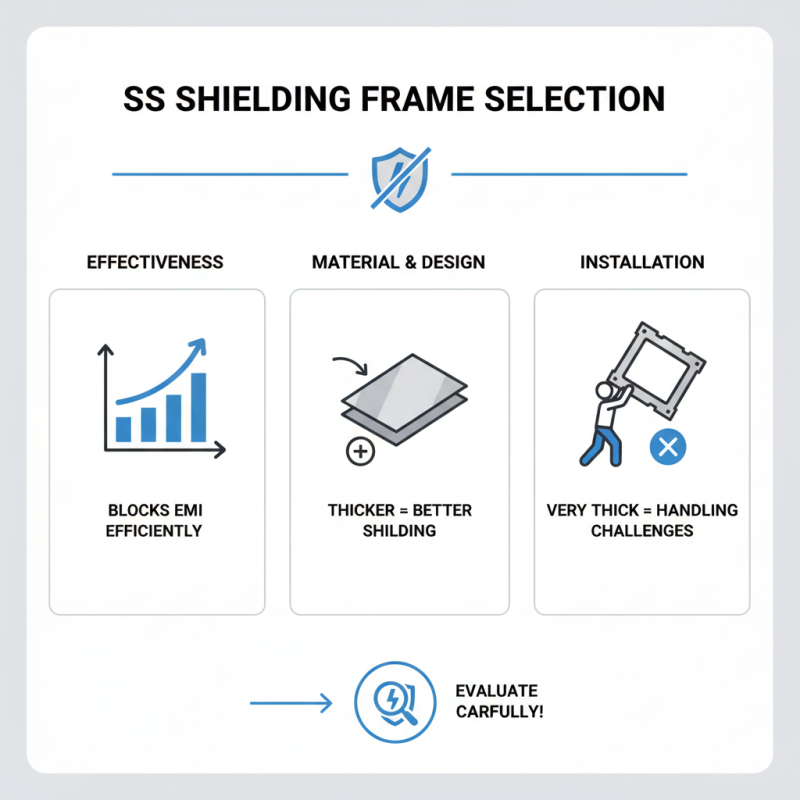

When choosing a stainless steel shielding frame, evaluating its effectiveness is crucial. The frame should block electromagnetic interference (EMI) efficiently. Consider the material thickness and design. Thicker materials generally offer better shielding. However, a very thick frame may pose challenges in handling and installation.

Compliance with various standards is another essential factor. Frames may need to meet certain industry regulations. Look for certifications that indicate adherence to these standards. Not all manufacturers provide clear information about compliance. This can lead to unnecessary risks in your project. It's vital to perform your due diligence.

Field testing the shielding frame is advisable. It helps to identify potential flaws in its design. Sometimes the specifications on paper do not match real-world performance. A frame may look good but fail in practical applications. Always be prepared for adjustments based on test results. This step can save time and resources down the line.

When budgeting for stainless steel shielding frames, it’s essential to evaluate your needs thoroughly. Prices can vary significantly based on size, thickness, and customization. For example, a recent report from the Metal Fabrication Institute indicates that standard frames can range from $500 to $2,500, depending on the specifications. While it’s tempting to choose the cheapest option, consider the long-term benefits of durability.

Think about your unique requirements. Will the frame need to withstand harsh environments? Are there special electromagnetic shielding needs? Sometimes, opting for a tailored solution may cost more initially but save money through reduced maintenance and increased lifespan. It's an investment in quality.

Here are a few tips: Start with a clear budget. Gather quotes from different suppliers, focusing on quality versus price. Assess the importance of additional features. Make a decision based on total cost of ownership, not just the upfront expense. Your frame should protect assets effectively while fitting within fiscal constraints. Consider both immediate costs and future expenses to avoid overspending. Reflect on these aspects as you make your choice.