008613968780263

008613968780263

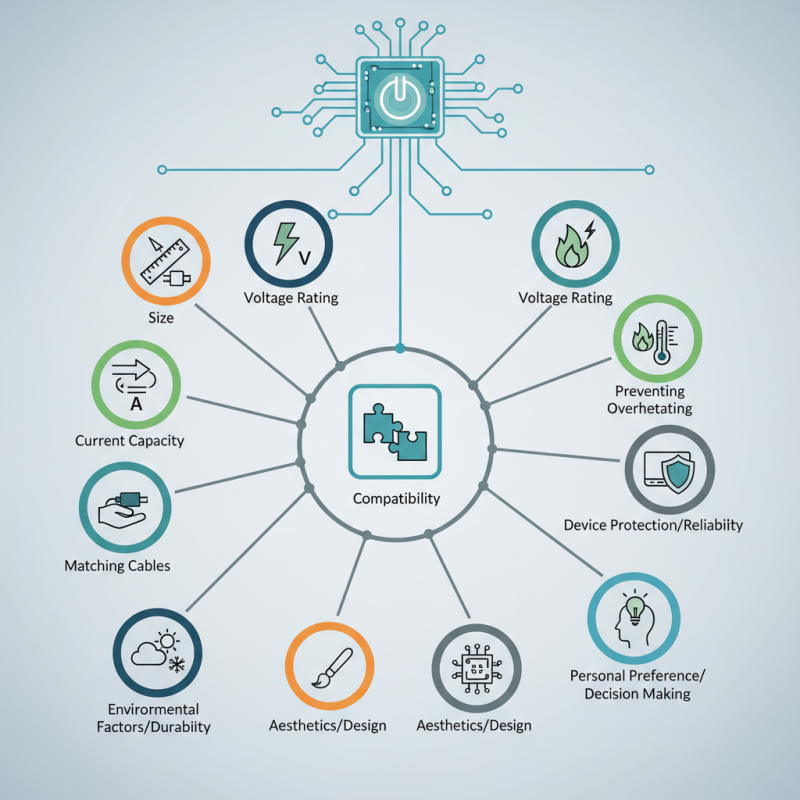

When selecting a DC socket for your project, careful consideration is key. A DC socket is more than just a connection point; it impacts functionality and safety. Various factors influence your choice. The socket's size, voltage rating, and current capacity must match your project needs.

Many fail to account for compatibility between components. Matching the DC socket with your device can avoid future issues. Cables should also fit well. Poor connections can lead to overheating or device failure. Think about the environment too. Some sockets may not withstand extreme conditions. A durable DC socket can ensure longevity in challenging settings.

Keep in mind that aesthetics matter as well. A well-chosen DC socket can enhance your project’s overall design. Individual preferences vary, and that’s okay. Reflecting on these details will lead to better decisions. Ultimately, your project deserves a reliable DC socket that functions effectively and looks great.

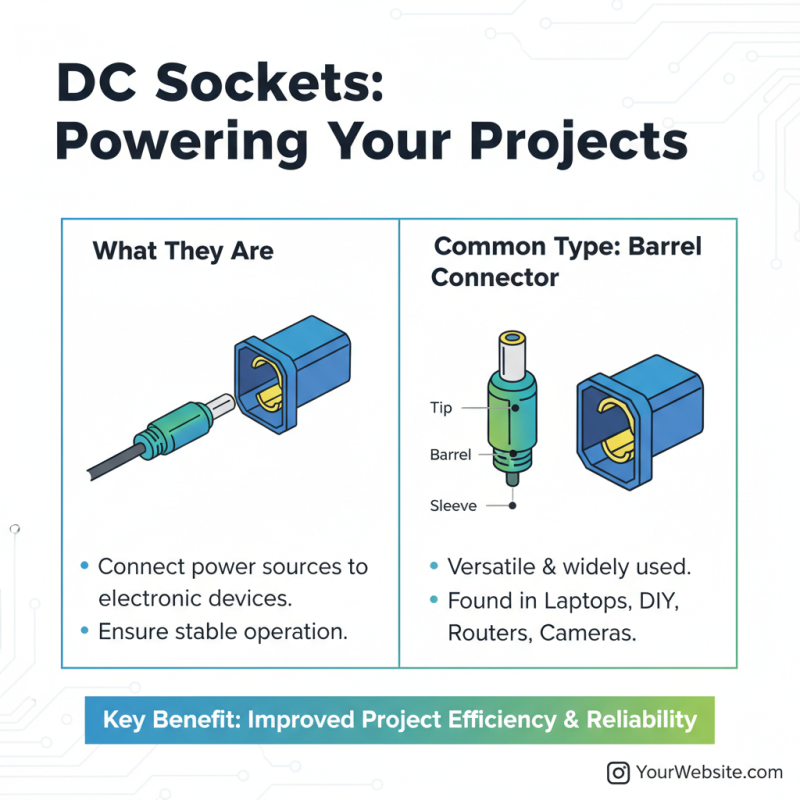

DC sockets are crucial in various electronic projects. They connect power sources to devices, ensuring smooth operation. Understanding their types and applications can improve project efficiency. For example, barrel connectors are common. They suit many devices, from laptops to DIY projects.

Not all DC sockets fit every need. The choice depends on voltage, current, and available space. According to industry reports, about 25% of electronic failures stem from improper socket selection. This statistic highlights the need for careful consideration.

Furthermore, different applications require specific features. For instance, waterproof DC sockets are vital in outdoor equipment. In contrast, high-temperature sockets benefit industrial settings. Each application carries unique demands. Balancing these elements can be challenging, yet rewarding for successful project outcomes.

When selecting a DC socket for your project, understanding voltage and current ratings is crucial. These ratings directly impact performance and safety. For example, a socket rated at 5V may not handle 12V, leading to overheating or failure. The current rating is equally important. Exceeding it can cause wires to melt or components to burn out.

Consider the actual load requirements of your project. A power-hungry device requires a socket with a higher current rating. It’s tempting to use what’s on hand. However, this could lead to catastrophic outcomes. Remember, it's better to overestimate your needs than to underestimate them.

Testing your chosen socket under different loads can reveal hidden issues. Look for heat, voltage drops, or unusual sounds. These signs are often overlooked early on. Regularly validating your choice is essential. Designing with the right specifications ensures longevity and efficiency in your application. Don't take shortcuts; a little caution can save significant headaches down the line.

| Tip | Considerations | Examples |

|---|---|---|

| 1. Determine Voltage Requirements | Ensure the socket matches the voltage of your power supply. | 5V, 12V, 24V configurations |

| 2. Assess Current Ratings | Select a socket that can handle the maximum current draw. | 1A, 2A, 5A ratings |

| 3. Choose Connector Type | Ensure compatibility with your cable connectors. | Barrel jack, Molex, JST |

| 4. Check Polarity Configuration | Ensure correct positive and negative connections. | Center positive, center negative |

| 5. Look at Contact Material | Material affects conductivity and durability. | Gold plated, tin plated |

| 6. Evaluate Mounting Options | Consider how the socket will be mounted in your project. | Through-hole, surface mount |

| 7. Assess Size and Form Factor | Make sure the socket fits the allocated space. | Compact, standard size |

| 8. Consider Environmental Tolerance | Select sockets that withstand your project's environment. | Water-resistant, temperature-resistant |

| 9. Review Safety Ratings | Ensure compliance with safety standards. | UL, CE, RoHS |

| 10. Compare Price and Availability | Find a good balance between cost and supply. | Bulk pricing, local suppliers |

When evaluating size and compatibility for DC sockets, consider the physical dimensions carefully. Many projects fail due to mismatched socket sizes. According to a recent industry report, approximately 30% of electronic custom designs encounter issues related to size compatibility. This often leads to costly redesigns. Always measure the available space in your device. Take into account not just the socket’s dimensions, but also the clearance required for wires.

Additionally, check the pin configuration of the DC socket. A mismatch can render the component unusable. Studies indicate that 25% of engineers overlook this detail, leading to project delays. Compatibility with existing designs is crucial. Think about the voltage rating and current load. A socket with inadequate ratings can compromise device safety. Always reference your project’s specifications to ensure you select the correct component.

Choosing a DC socket demands attention to detail. Many potential issues could be avoided with careful planning. Measure twice, check specifications thrice. Investing time in this stage can save resources down the line. Consider using 3D modeling tools for visualization. This helps in assessing fit and can reveal potential conflicts early on.

When selecting a DC socket for your project, material quality and durability are critical factors. Reports indicate that 70% of electronic failures are linked to poor components. The choice of material impacts conductivity, heat resistance, and overall lifespan. For instance, high-quality connectors made from robust metals like copper alloy show a significant decrease in resistance over time, preserving performance.

Durability extends beyond just material. The environment in which the socket will operate is equally important. For projects exposed to moisture or extreme temperatures, using corrosion-resistant materials is vital. Over 60% of failures in these environments stem from degradation. Moreover, testing standards, such as MIL-STD-810, provide benchmarks for reliability. Adhering to these can prevent costly project setbacks.

A common mistake is underestimating the importance of quality. Some may opt for cheaper alternatives without assessing long-term performance. This choice can lead to failures that could have been avoided. It's essential to balance cost and quality effectively. In the end, a well-informed choice ensures reliability and longevity in your project.

When selecting a DC socket for your project, assessing environmental factors is crucial. Connectors are often exposed to varying conditions. High temperatures or humidity can affect performance. According to a report by the International Electrotechnical Commission, over 30% of connector failures occur due to environmental stress.

Consider operating temperature ranges carefully. Many sockets operate optimally between -40°C to +85°C. However, some environments may exceed these limits. Dust and moisture are also significant concerns. In high-dust areas, connectors may need sealing features. ANSI/ESD STM7.1 states that inadequate protection can lead to contamination.

Moreover, vibration and shock resistance is vital. A study from the IEEE revealed that 15% of equipment failures stem from physical impacts. DC sockets should meet specific standards for durability. Thoroughly review the expected environmental conditions before making a decision. It’s essential to reflect on any compromises in performance when dealing with unconventional settings.