008613968780263

008613968780263

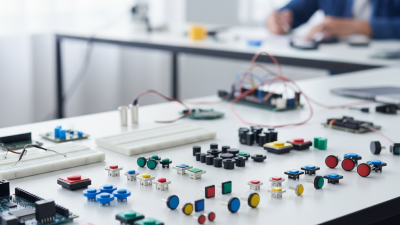

In the rapidly evolving field of electronic components, selecting the right Metal Push Button for your project needs can significantly enhance both functionality and aesthetic appeal. As highlighted by industry expert Dr. Samantha Lee, a leading engineer in user interface design, "The choice of a Metal Push Button is not just about durability; it's about creating an experience that users resonate with." This statement underscores the importance of carefully considering various factors such as size, shape, and feedback mechanism when integrating these components into your designs.

Metal Push Buttons are lauded for their robustness and sleek appearance, making them ideal for a multitude of applications, from consumer electronics to industrial machinery. The tactile response and visual impact they offer can elevate the overall user experience, turning a simple interaction into an engaging moment. As you delve into the selection process, understanding the specific requirements of your project will allow you to make more informed decisions, ensuring that your chosen push button not only meets functionality needs but also aligns with the desired aesthetic and user engagement. In this discussion, we will explore essential criteria to consider when choosing the ideal Metal Push Button for your upcoming projects.

When selecting a metal push button for your project, understanding the various types available in the market is crucial. Metal push buttons can be categorized primarily based on their function, design, and durability. Common types include momentary, latching, and illuminated buttons. Momentary push buttons are typically used in applications where temporary activation is needed, such as in machinery and electronic devices. Latching buttons, on the other hand, maintain their state until pressed again, making them ideal for toggle functions in various systems.

In addition to functionality, the design of metal push buttons can vary, impacting both aesthetics and user experience. Some buttons come with a smooth, polished finish, while others may feature a rugged texture for better grip. The size and mounting style are also important considerations; some buttons are designed for panel mounting, while others can be surface mounted. Furthermore, choosing the right material is essential for ensuring durability and resistance to environmental factors. Stainless steel, for instance, offers high strength and corrosion resistance, making it suitable for harsh conditions. By considering these factors, you can select a metal push button that not only meets your project's technical requirements but also enhances its overall design.

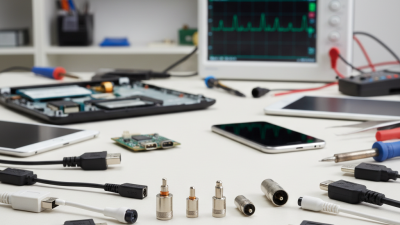

When selecting a metal push button for your project, several key factors must be taken into account to ensure functionality, durability, and compatibility. One of the primary considerations is the environmental conditions the button will face. For instance, according to a report by MarketsandMarkets, the global metal push button switch market is projected to reach $1.2 billion by 2026, reflecting the increasing demand for robust components in challenging environments. Thus, it's critical to choose a button with an appropriate IP (Ingress Protection) rating that corresponds to the exposure to dust, moisture, and other elements in your application.

Another essential factor is the button's operational characteristics, including its actuation force, travel distance, and electrical specifications. Studies indicate that user ergonomics can significantly impact user satisfaction and operational efficiency. A survey conducted by the Human Factors and Ergonomics Society found that buttons requiring excessive force or with poor tactile feedback can detrimentally affect user experience, leading to operational errors. Therefore, understanding the required specifications, such as voltage ratings and current capacities, ensures that the button integrates seamlessly into the electrical system of your project, enhancing user interaction and reliability.

When selecting the right metal push button for your project, it is crucial to evaluate its specifications and features meticulously. Start by considering the button's material and finish, as these factors not only dictate aesthetics but also determine durability and resistance to environmental conditions. For instance, stainless steel buttons are often favored for their corrosion resistance, while those with special coatings can enhance aesthetic qualities and protect against wear. Additionally, think about the button’s IP rating, which indicates its level of protection against dust and water ingress—essential for applications in harsh environments.

Another critical aspect to evaluate is the button’s electrical characteristics, including voltage and current ratings. Ensure that the push button is compatible with your system’s specifications to prevent failures due to overloading. It is also important to consider the actuation force and travel distance, which affect the user experience. Choosing a button that provides the right tactile feedback can enhance usability, making it easier for users to interact with the interface. Finally, assess any additional features, such as LED indicators or momentary vs. latching functionality, to find the most suitable component for your specific application.

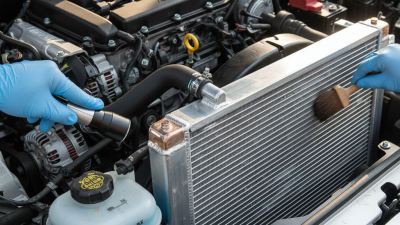

When selecting a metal push button for your project, evaluating its durability and environmental resistance is crucial. The intended application conditions, such as temperature fluctuations, humidity, and exposure to chemicals, should guide your choice. Materials like stainless steel or anodized aluminum are often preferred for their strength and resistance to corrosion. These materials not only endure mechanical wear but also resist the effects of harsh environments, making them suitable for outdoor applications or industrial settings.

Additionally, understanding the IP (Ingress Protection) rating of a push button can further inform your decision. An IP rating indicates the level of protection against solids and liquids, which is vital for electronics exposed to dust or moisture. For projects in particularly challenging environments, such as those subjected to frequent washing or exposure to corrosive substances, opting for push buttons with higher IP ratings will enhance longevity and reliability. Thus, careful assessment of both durability and environmental resistance not only ensures the longevity of the component but also contributes to the overall success of the project.

| Button Type | Material | Durability Rating | Environmental Resistance | Operating Temperature (°C) |

|---|---|---|---|---|

| Momentary Switch | Stainless Steel | IP67 | Waterproof, Dustproof | -30 to 70 |

| Latching Button | Brass | IP65 | Moisture Resistant | -20 to 60 |

| Key Lock Switch | Aluminum | IP68 | Chemical Resistant | -40 to 85 |

| Emergency Stop | Stainless Steel | IP69K | High Pressure Washable | -20 to 75 |

When installing metal push buttons, proper positioning and secure connections are crucial for optimal functionality. Start by selecting an appropriate location that ensures easy access for users. The surface should be clean and even; any debris or irregularities can affect the button's responsiveness and lifespan. Use appropriate mounting hardware that comes with the button, which is designed to withstand both mechanical strain and environmental factors. Ensure that the push button's electrical connections are well-insulated and protected from moisture and dust to prevent short circuits and corrosion.

Regular maintenance of metal push buttons can significantly enhance their durability and performance. Periodic cleaning is essential, especially in environments prone to dust or contaminants. A gentle wipe with a damp cloth can eliminate grime without damaging the metal surface. Additionally, inspect the buttons for wear and tear, paying close attention to the actuator mechanism. If any signs of degradation are visible, consider replacing the component to avoid potential failures. Lastly, checking the electrical connections regularly can help maintain the consistency in performance and prevent unexpected outages. Following these guidelines will help ensure your metal push buttons operate effectively for years to come.