008613968780263

008613968780263

Choosing the right Extrusion Heat Sink is crucial for project success. As industry expert Dr. Emily Chen states, "A well-chosen heat sink can enhance performance significantly." This highlights the stakes involved in selecting the proper thermal management solution.

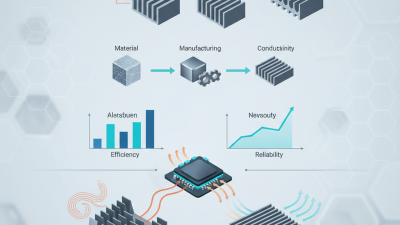

Extrusion Heat Sinks offer a range of designs and materials. They are often preferred for their efficiency and effectiveness in dissipating heat. However, not all extrusion designs suit every project. Factors such as size, weight, and thermal conductivity must be carefully evaluated.

Many designers underestimate the complexity of this choice. The wrong heat sink can lead to overheating, reducing life expectancy. It's essential to prioritize functionality over aesthetics. Understanding the specific needs of your project is vital. Ultimately, the decision requires thoughtful consideration to ensure optimal performance.

Determining the thermal requirements for your heat sink design is crucial. Start by analyzing the heat generated by your components. Measure their power consumption and assess how that translates into heat. You need precise calculations here. If the figures are off, the entire design could fail.

Consider the environment where the heat sink will operate. Will it be in a confined space? How much airflow will it receive? Each factor changes the effectiveness of your heat sink. For instance, higher ambient temperatures can lead to reduced efficiency.

Finally, account for safety margins. Overheating can damage components. Relying too much on ideal conditions may backfire. A heat sink that works in theory could struggle in real-world applications. Test different designs to find a balance between size and thermal efficacy. Adjust based on findings. Every project is unique—don't assume one size fits all. Learning from these adjustments can lead to a more successful design outcome.

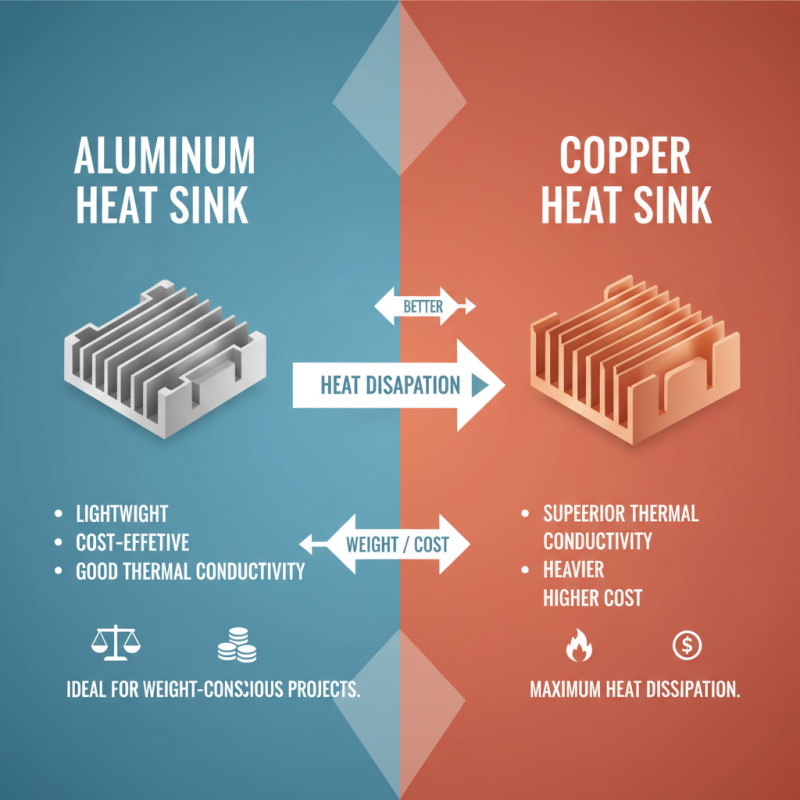

When selecting a heat sink, understanding the material properties of aluminum and copper is crucial. Aluminum is lightweight and cost-effective. Its thermal conductivity is decent, making it suitable for many applications. However, it may not dissipate heat as efficiently as copper. For projects where weight is a concern, aluminum might be ideal.

On the other hand, copper offers superior thermal conductivity. It transfers heat away more effectively, which can enhance performance in high-temperature scenarios. However, copper is heavier and more expensive. The choice between these materials turns complex. It’s essential to consider the specific requirements of your project. Often, a common dilemma arises: prioritize weight or heat dissipation?

It’s important to test different materials under your project’s conditions. Some might find that aluminum suffices, while others require copper's advantages. Reflecting on this can lead to better choices and efficient designs. Understanding the balance between cost, weight, and performance may require some trial and error. Each project presents unique challenges, pushing designers to adapt and innovate.

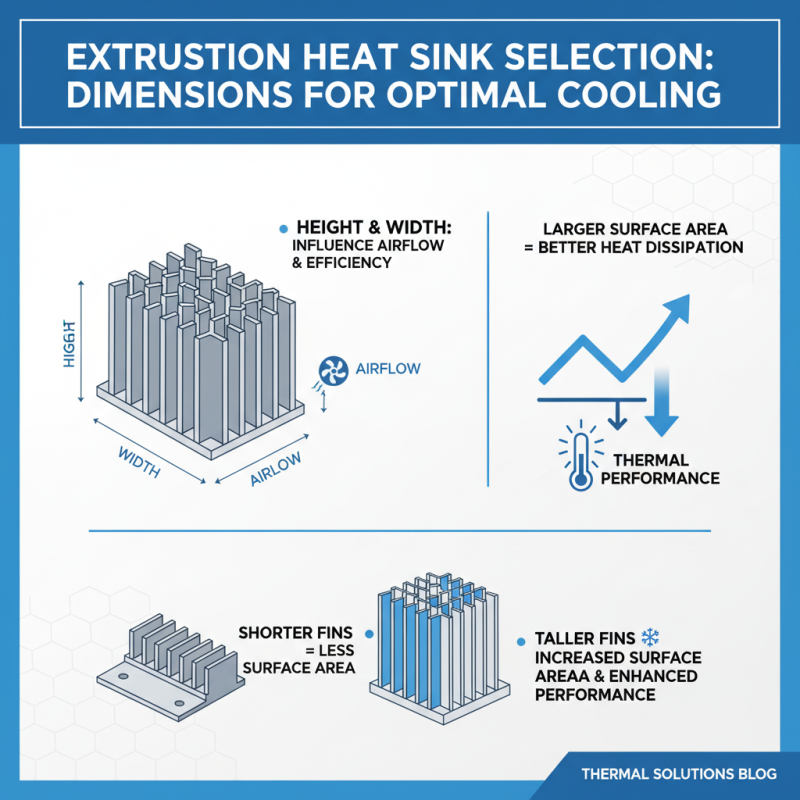

When selecting the right extrusion heat sink, dimensions play a critical role. The height and width influence airflow and overall cooling efficiency. According to industry reports, heat sinks with larger surface areas can dissipate heat more effectively. A design that incorporates taller fins can increase surface area, enhancing thermal performance.

Consider fin design carefully. Ideally, fins should be spaced to allow for optimal airflow. More fins improve heat dissipation but can also restrict airflow if too crowded. It’s a balancing act. A study shows that increasing fin density by 30% can enhance cooling performance by up to 15%, but only if airflow remains unobstructed.

Tips: Measure your specific application needs before finalizing dimensions. Always remember that perfect designs often require adjustments in real-world applications. Don't hesitate to experiment with different configurations. Each project is unique, and what works perfectly for one may need tweaking for another. Reflect on performance data after testing. Continuous improvement is essential in heat sink design.

When selecting an extrusion heat sink, airflow plays a crucial role. Ambient conditions can significantly impact heat dissipation efficiency. According to a study from the Thermal Management Institute, heat sinks in environments with higher airflow can dissipate 30% more heat. However, stagnant air can reduce efficiency, leading to hotspots.

It's essential to analyze airflow patterns in your project area. For example, when placing a heat sink near a fan or an exhaust vent, the cooling potential increases. Fans can create a directed airflow, maximizing cooling. In less ideal conditions, such as enclosed spaces, alternative strategies may be needed. Some findings suggest adding passive cooling solutions, like fins or additional heat spreaders, can help.

Moreover, humidity levels also matter. High humidity can affect thermal conductivity. A report by the International Journal of Heat Transfer showed that in humid conditions, heat transfer rates could drop by 15%. This reduction can complicate heat management strategies. Awareness of these factors is vital for optimizing thermal designs. Adjusting your approach based on these insights can lead to better performance.

Selecting the right fin density for an extrusion heat sink is critical. It's not just about cooling performance; it also impacts manufacturing costs. A report by the Thermal Management Association suggests that a higher fin density can improve heat dissipation by up to 30%. However, this increase in efficiency often leads to higher production expenses. The challenge is finding the right balance between performance and budget.

Fin density affects airflow and thermal conductivity. Denser fins yield better thermal performance, yet they can complicate the manufacturing process. For instance, increasing fin density might result in higher material waste. The industry average indicates that going beyond a certain density can yield diminishing returns on heat dissipation, with added costs that may not justify the improvement.

In practice, engineers have experienced difficulties in scaling density effectively. Some report challenges in achieving uniform heat distribution across fins. Compromises might be necessary, trading off peak performance for reduced costs. The need for assessment in design phases cannot be overstated. Not every project requires the highest fin density for optimal results.

| Fin Density (Fins/cm²) | Thermal Performance (W/K) | Manufacturing Cost ($/unit) | Weight (g) | Recommended Application |

|---|---|---|---|---|

| 30 | 15 | 25 | 100 | LED Lighting |

| 50 | 20 | 30 | 150 | Power Electronics |

| 70 | 25 | 35 | 200 | High-Performance Computing |

| 90 | 30 | 40 | 250 | Industrial Machinery |